IFASIntegrated Fixed-Film Activated Sludge

IFAS is a new and efficient biochemical process combining activated sludge and biofilm.

IFAS process combines the advantages of activated sludge and biofilm, which can not only efficiently remove nitrogen and carbon, but also harmonize the selectivity of microbial nitrogen and phosphorus removal.

IFAS is characterized by small footprint, small mud production and strong impact load resistance, especially suitable for the upgrading of sewage plants and the biochemical treatment of industrial wastewater.

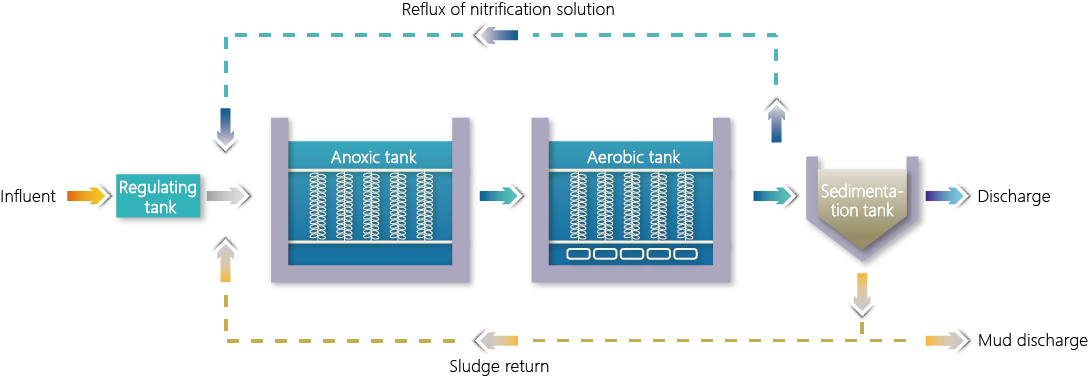

Immobilized biofilm-activated sludge (IFAS) process is based on the combination of biological filler and activated sludge reflux system in contact oxidation process.

The core technology of IFAS process is biological filler, mainly including rope fiber filler (FBBR) and suspension filler (MBBR), which can improve the sludge concentration of the system and strengthen the biochemical treatment effect. It has excellent treatment effect for micro-polluted municipal wastewater and high-pollution industrial wastewater.

Compared with the traditional activated sludge process, it has the advantages of small footprint, low sludge yield and strong impact load resistance.

The synergistic effect of mud-film two-phase functional microorganisms can make the non-dominant bacteria (nitrifying bacteria, ammonia oxidizing bacteria) remain in the form of biofilm, increase the functional diversity of microorganisms, and increase the biomass of nitrifying bacteria in aeration tank without increasing tank capacity and sludge yield, thus improving the total biomass of biological system.

It can not only effectively remove nitrogen and carbon, but also reconcile the sludge age contradiction of biological nitrogen and phosphorus removal.

N: Nitrifying bacteria, slow propagation speed, mud age: about 25d

P: Phosphorus accumulating bacteria, fast propagation speed, mud age: 3d

The EPS content of suspended sludge is 2-4 times that of biofilm. IFAS connected with MBR has better effect on anti-FOULING of MBR membrane.

Application Area

IFAS fillers are widely used for:

Printing and dyeing wastewater, coking wastewater, food wastewater, chemical wastewater, municipal wastewater, aquaculture wastewater, photovoltaic wastewater, PCB wastewater, etc.

Problems that IFAS can solve

The IFAS process has great advantages in wastewater treatment. With rich project cases and research experience, our team uses the IFAS process to solve their pain points when they face the following intractable diseases.

Improved drainage standards

On the basis of not increasing the pool capacity, it is required to upgrade the effluent level B to level A.

Old craftsmanship, no production and transformation

The production enterprises shall not stop production and transform the sewage station without affecting the production progress.

High cost of chemical agent, operation and maintenance

The traditional activated sludge method needs to add chemicals and arrange full-time personnel for management.

AN and TN is not up to standard

The removal rate of COD reaches the standard, but the removal effect of AN and TN is not good.

The biofilm hanging effect is not good, and the removal rate is unstable

The biofilm is sparse, and the water quality fluctuates between good and bad.

The contradiction between nitrogen and phosphorus removal

Nitrogen removal and phosphorus removal cannot be performed simultaneously.

IFAS case introduction

Wastewater treatment case of a paper factory in Guangzhou

After the renovation, the wastewater plant was treated by hanging biofilm with IFAS filler. After testing and comparing the water quality data before and after treatment, it can be known that the COD removal rate reaches 63.3%, TN removal rate reaches 46.6%, NH3 removal rate reaches 87.9%. After the treatment, the water quality is discharged up to standard and has been running well.